New pfas treatment results & ghg reduction ~ November-December, 2019

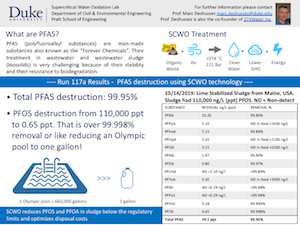

During November we have received the groundbreaking results of our latest fecal sludge & PFAS treatment campaign runs. The effluent analysis is showing an average of 99.9% total PFAS removal from three different PFAS contaminated sludges. This is an important milestone for the SCWO technology, showing its relevance not only in developing countries as a cost-effective decentralized solution for sanitation, but also for developed countries looking to mitigate emerging contaminants. Click the report names below to see the complete analysis of a particular campaign run.

During November we have received the groundbreaking results of our latest fecal sludge & PFAS treatment campaign runs. The effluent analysis is showing an average of 99.9% total PFAS removal from three different PFAS contaminated sludges. This is an important milestone for the SCWO technology, showing its relevance not only in developing countries as a cost-effective decentralized solution for sanitation, but also for developed countries looking to mitigate emerging contaminants. Click the report names below to see the complete analysis of a particular campaign run.

Lime stabilized sludge (ME)

Primary sludge (ME)

Primary sludge (MI)

In other news, we have completed an initial greenhouse gas (GHG) reduction analysis for future commercial SCWO units. We can estimate the methane amount (a potent GHG) generated by the natural decay of organic wastes when disposed in the environment, and SCWO’s ability to alleviate it. Our analysis shows that the system could mitigate 6 tons of CO2e for every 1 ton of waste treated. In addition, it can reduce electricity demands for treating sludge by 40%. Lastly, it can also eliminate transportation emissions from hauling sludges to landfills.

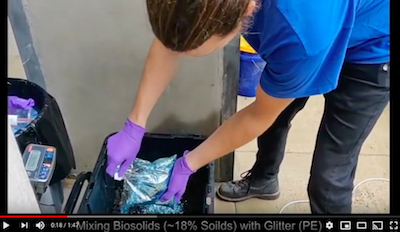

treating fog & plastic ~ October, 2019

October was a very exciting and fun month for the SCWO team. We commissioned our new liquid/solid particle separation setup with the innovative hydro-cyclone we designed and 3D printed here at Duke. This is another important milestone in the effluent’s post-treatment processing – designed to produce marketable products. Another fun part of this month consisted of our very own glitter party! We co-treated plastic glitter for the first time, together with biosolids - while using FOG (Fat, Oil, Grease) as co-fuel. Preliminary results are showing >99.5% conversion of the organics to CO2 and clean water! This is a great demonstration of how the SCWO system can serve as an on-site decentralized waste treatment plant, embedded in communities. Check out the video compilation of this run here.

Gas/liquid separator setup ~ September, 2019

When analyzing the results from our recent residence time experiment, we decided to update the system’s gas/liquid separation hardware to get even more accurate flow and concentration readings. In parallel, we updated the PI software configurations to collect and log this data automatically and present it in real-time.

When analyzing the results from our recent residence time experiment, we decided to update the system’s gas/liquid separation hardware to get even more accurate flow and concentration readings. In parallel, we updated the PI software configurations to collect and log this data automatically and present it in real-time.

commissioning of new slurry pump ~ August, 2019

After several months of troubleshooting, we have successfully commissioned our new slurry pump. In the next quarter we will test increasing flowrates and thicker slurries. In our ongoing efforts to productize the system and streamline its operation, we have updated our HMI with the new pump, a new set of critical alerts and implemented an automated KPI tool to our dashboard, which facilitates operation and post-run analysis.

After several months of troubleshooting, we have successfully commissioned our new slurry pump. In the next quarter we will test increasing flowrates and thicker slurries. In our ongoing efforts to productize the system and streamline its operation, we have updated our HMI with the new pump, a new set of critical alerts and implemented an automated KPI tool to our dashboard, which facilitates operation and post-run analysis.

Lastly, when performing system maintenance after the 100-hour run, the team came up with a way to increase capillaries lifetime by configuring a multi-diameter setup, which has been completed this month.

residence time experiments ~ July, 2019

After the success of the 100-hour run, the team was ready for its next important milestone - the residence time experiment. The objective of this campaign run was to quantify to which extent the residence time of slurry in the reactor, and different oxygen levels affect treatment results. Preliminary results are showing:

After the success of the 100-hour run, the team was ready for its next important milestone - the residence time experiment. The objective of this campaign run was to quantify to which extent the residence time of slurry in the reactor, and different oxygen levels affect treatment results. Preliminary results are showing:

- Longer residence timeseems to positively impact the conversion of COD and total nitrogen.

- Relationships for residence time-residual oxygen to reach given performances are likely feedstock-dependent.

- These results contribute to our treatment performance knowledge base which is critical to the proper sizing and operation of large scale SCWO systems.

Additional system updates this month included adding the airflow control valve’s feedback signal to the PLC, for better real-time monitoring and control. At the same time, we started designing a new capillary setup to mitigate corrosion effect during cooldown.

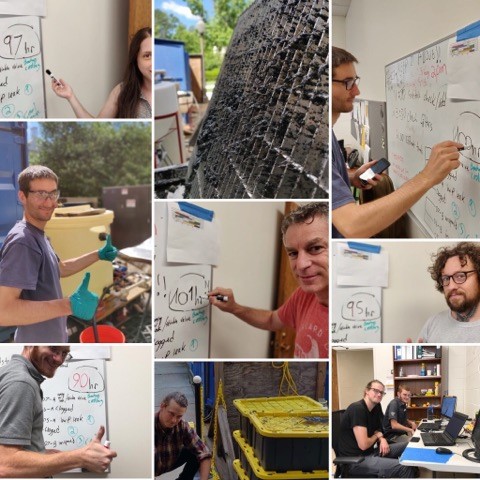

100 Hour Run ~ JUNE, 2019

This month we have achieved our long-awaited milestone of running the SCWO unit consecutively for 100 hours! This run shows the system’s maturity and ability to work around the clock in treating residual solids. In preparation for this long run, we picked up over 30 tubs of biosolids from Durham’s WWTP, upgraded the system’s wiring and extended our cooling loop. The team operated the system 24/7 for five days, treating ~2 tons of biosolids.

This month we have achieved our long-awaited milestone of running the SCWO unit consecutively for 100 hours! This run shows the system’s maturity and ability to work around the clock in treating residual solids. In preparation for this long run, we picked up over 30 tubs of biosolids from Durham’s WWTP, upgraded the system’s wiring and extended our cooling loop. The team operated the system 24/7 for five days, treating ~2 tons of biosolids.

In other news, the results for our second landfill leachate experiment performed last month are in! We are glad to share that the system treated organic components successfully and that it flawlessly handled the highly saline feedstock. Review the complete report card.

Building a product ~ April-May, 2019

At the beginning of April, we hosted representatives from the Army Futures Command (AFC), who were interested in learning how SCWO can be utilized to solve sanitation challenges and save soldiers’ lives in FOBs (Forward Operating Bases) and main operation bases.

During April and May we have focused on advancing the automation and productization of the SCWO pilot plant on campus. We commissioned our operation intelligence software (OSIsoft) to analyze temperature and pressure trends for different flowrates and feedstocks in real time, while streamlining our monitoring of Key Performance Indicators (KPIs) and control abilities during operation. In addition, we added a new co-fuel injection pump, to help adjust the reaction temperatures quickly and easily through the HMI. Lastly, we optimized the feeding loop lines to facilitate more concentrated slurry pumping and improve pressure stabilization. All of these upgrades will enable us to decrease number of operators per shift and advance our experiments with the feedstock’s residence time in the reactor and optimizing the system’s performance for each waste type.

Gates Foundation visit & microplastics treatment ~ March, 2019

This month we were honored to host Dr. Doulaye Kone, deputy director of the WaSH program and Sun Kim - our program officer at the Bill & Melinda Gates foundation. They witnessed a live demonstration of the SCWO system in action, as well as its capability of co-treating fecal sludge, food waste and plastic wastes, while using cooking oil to supplement the calorific value of sludge and enable off-the-grid operation.

Preliminary results show a reduction of the organics by over 99.2% when treating biosolids, plastics and waste oil with simultaneous production of clean water. We are also glad to share the preliminary results for treating landfill leachate, with a conversion of over 98.2%.

During March, we continued to upgrade the system to further improve our real-time data monitoring and analysis capabilities. We have also upgraded the air and water flow controls to facilitate further experimentation with OpEx reduction and treatment quality, by increasing the dynamic range of air flow. Lastly, we have installed an inline pH and conductivity probe to monitor the effluent in real-time.

Towards the end of the month, we received the new custom-made high efficiency plunger pump, which can potentially reduce the power consumption of our existing slurry pump and enable us to experiment with even more concentrated slurries and higher flowrates.

Landfill leachate & food scraps ~ February, 2019

This month we treated new feedstocks and used new co-fuels, as well as upgraded our gas sensors setup and focused on improving energy effeciency. We collaborated with Duke Dining and several restaurants on campus to collect used oil and food scraps, to use as co-fuel while treating fecal sludge. The slurry mixed with food waste had a high conversion rate to clean water (over 99.8%) and this successful experiment showed that the SCWO unit can efficiently treat and co-treat other community generated waste types. In addition, we treated landfill leachate for the first time and preliminary results are showing over 99% conversion to clean water. The fecal sludge we used at this run was sent by wastewater treatment plants of Durham and Chapel Hill with whom we have been collaborating to further test and prepare the system for its first on-site demonstration. At the same time, we looked into improving and streamlining our gas sensors data collection and analysis, by fabricating a new setup which includes new sensors and additional calibration functions where needed. As we are getting ready to complete the design for the first commercial model of the SCWO system, we have started decreasing the flow in our water recycle loop gradually when operating the unit, while targeting specific airflow (oxygen) to sustain an effective reaction in a more resilient manner. Coming up next are microplastics experiments - stay tuned!

Longer, smoother runs ~ January, 2019

We opened 2019 with a run campaign of over 50 hours of continuous processing slurry. After investigating and mapping periodical pressure drops throughout the runs, we have now further improved our flow and pressure controls. We experimented with various capillaries sizes and operational configurations of the gas and liquid separators to enhance the effluent’s depressurization process. This enabled us to enjoy a very steady and stable reaction and perform smoother longer runs.

During these runs, we experimented with new co-fuels - vegetable oil and spent motor oil which proved to be as effective as IPA and diesel. This is great news since it shows the flexibility of the system to use different waste oils as co-fuel or to co-treat fecaland other wastes - a true Omni processor! Next on our list if food scraps – more updates coming soon!

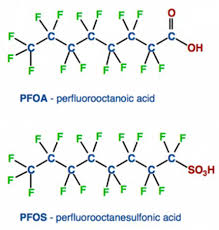

PFOS/PFOA treatment results ~ December, 2018

During December, the hard work of improving our monitoring and control systems has paid off - where we experienced a smooth (even boring) run in which the SCWO team operated the system around the clock for two consecutive days. After further experimentation with treating PFOS/PFOA micro-pollutants with the SCWO system, we are glad to share the latest results in which we have reached the 99.1% elimination of PFOS and 99.9% of PFOA. Lastly, this month we launched our pilot program, in which we are inviting facilities to send us their most difficult-to-dewater and treat waste types from around the country, to perform pilot runs with the SCWO unit on Duke Campus – more updates coming soon! If you are interested in participating, please contact us at scwo@duke.edu

During December, the hard work of improving our monitoring and control systems has paid off - where we experienced a smooth (even boring) run in which the SCWO team operated the system around the clock for two consecutive days. After further experimentation with treating PFOS/PFOA micro-pollutants with the SCWO system, we are glad to share the latest results in which we have reached the 99.1% elimination of PFOS and 99.9% of PFOA. Lastly, this month we launched our pilot program, in which we are inviting facilities to send us their most difficult-to-dewater and treat waste types from around the country, to perform pilot runs with the SCWO unit on Duke Campus – more updates coming soon! If you are interested in participating, please contact us at scwo@duke.edu

Treating primary sludge ~ November, 2018

This month the SCWO team has traveled all the way to China, to participate in the much talked about Reinvented Toilet Expo, organized by the Bill & Melinda Gates foundation. We had the chance to discuss our technology and progress to date with government officials and potential commercial partners. We have also successfully treated primary sludge for the first time, sent to us from Delphi - IN, where we reached a COD conversion of +99.1% and with just 234 mg/L of ammonia remaining in the effluent. At the same time, we continued experimenting with treating PFOS and PFOA spiked feedstock and will share the latest updates as soon as we process the results. Having the new team members onboard enabled us to further our data analysis efforts and improve the system’s operational costs by improving our heat exchanger performance and reducing excess oxygen amount. Lastly, we were welcomed by the OWASA’s wastewater treatment plant team at Chapel Hill where we toured the facility and discussed possible future collaboration.

Treating concentrated slurries ~ October, 2018

October was all about treating higher percent solids slurries. The reason for pursuing this objective is twofold: firstly, in order for the system to reach the Gates foundation's objective of 5 cents per person a day (CapEx + OpEx), we are focusing on reducing/eliminating the use of additional co-fuels to achieve autothermal reaction using only the energy embedded in the waste. This could be achieved at 12-16% solids. Secondly, in developed countries, it is current practice to dewater biosolids to decrease their volume to decrease costs of transportation and tipping fees. This means that the biosolids coming off the belt-press or centrifuge in a wastewater treatment plant, would usually contain ~16-22% solids. The closer we get to this range, the less pre-treatment the feedstock would require when implementing the system in existing wastewater treatment plants.

October was all about treating higher percent solids slurries. The reason for pursuing this objective is twofold: firstly, in order for the system to reach the Gates foundation's objective of 5 cents per person a day (CapEx + OpEx), we are focusing on reducing/eliminating the use of additional co-fuels to achieve autothermal reaction using only the energy embedded in the waste. This could be achieved at 12-16% solids. Secondly, in developed countries, it is current practice to dewater biosolids to decrease their volume to decrease costs of transportation and tipping fees. This means that the biosolids coming off the belt-press or centrifuge in a wastewater treatment plant, would usually contain ~16-22% solids. The closer we get to this range, the less pre-treatment the feedstock would require when implementing the system in existing wastewater treatment plants.

Preparations for these runs included installing new transducers along the slurry line and mixing tee, so we can have clear indications of pressure buildups in critical areas, and to better our ability to mitigate these while the system is running. We ended up treating slurries of up to 13.9% solids - a point where we can eliminate the use of co-fuel and sustain a powerful reaction just by converting waste to energy. During our experiments, we started using diesel as co-fuel (rather than IPA), which is a more common fuel source around the world with higher energy contents per volume. We were very pleased with the system performance while using very small amounts of diesel (the more concentrated the slurry is, the less co-fuel is required).

In addition, we continued to experiment with PFAS spiked feedstocks where preliminary results show a conversion of 98.95 % (PFOS) and 99.98% (PFOA) - more data to come soon. Lastly, we continued upgrading the system by adding a cover to the hopper, updated the PLC with new transducers and furnace controls as well as calibrating the water pump.

System upgrades ~ September, 2018

September was an eventful month for the SCWO team - we welcomed two new team members joining us – Jon Ricker (environmental advocate and an Indy film director) and David Ballenghien (SCWO pioneer and ex-Innoveox engineer). During this month, we performed a lot of upgrade and maintenance work on our pilot plant. We started by replacing old furnace parts to improve its decreasing performance in previous runs. We inspected the heat exchangers and performed maintenance to the water and slurry pumps, as well as the air compressor. We then updated our PLC and HMI to reflect the new updates and to incorporate algorithms that enable us to improve startup and shutdown time and better visualization of the system’s KPIs. The design for new high temperature gas/liquid separation vessels has been completed and the search for a fabricator in underway. In addition, we have set up a micron filter to filter the effluent and separate the clean water from the minerals to have a tighter control on our materials balance and further minerals properties’ investigation. This setup also enables us to test and integrate an on-site filtration solution, for water reuse. We are now ready for next month's increased percent solids testing – stay tuned!

September was an eventful month for the SCWO team - we welcomed two new team members joining us – Jon Ricker (environmental advocate and an Indy film director) and David Ballenghien (SCWO pioneer and ex-Innoveox engineer). During this month, we performed a lot of upgrade and maintenance work on our pilot plant. We started by replacing old furnace parts to improve its decreasing performance in previous runs. We inspected the heat exchangers and performed maintenance to the water and slurry pumps, as well as the air compressor. We then updated our PLC and HMI to reflect the new updates and to incorporate algorithms that enable us to improve startup and shutdown time and better visualization of the system’s KPIs. The design for new high temperature gas/liquid separation vessels has been completed and the search for a fabricator in underway. In addition, we have set up a micron filter to filter the effluent and separate the clean water from the minerals to have a tighter control on our materials balance and further minerals properties’ investigation. This setup also enables us to test and integrate an on-site filtration solution, for water reuse. We are now ready for next month's increased percent solids testing – stay tuned!

Straight feed ~ August, 2018

Following the commissioning of the new pre-feed setup last month, we proceeded to testing straight feeding the system, in order to facilitate the unit’s operation. While at steady state, we started feeding the auger with biosolids and water (without premixing and diluting them in advance) where they were initially mixed to form a slurry. The slurry went through the grinder and was pumped into the system through the lobe pump quickly and smoothly. This feeding process enabled us to test different slurry thickness levels, streamlining our processes as well as saving valuable time on pre-run preparations.

As we prepare for treating higher percent solid slurries in the next quarter, we have designed and installed few new bypass and flush ports to facilitate clearing the different pipes during operation and maintenance.

We continued to treat WAS slurry this month and reached the following removal percentage: COD - 98.8%, total nitrogen - 90.3%, phosphorous - 96.7%.

New pre-feed pump set up installed and commissioned ~ July, 2018

This month we have enhanced our slurry preprocessing and feeding system in several ways to streamline our system’s ability to treat high percent solids and high viscosity slurry streams. The new pre-feed pump set up includes an auger, grinder and a lobe pump. The Auger fed lobe pump will allow us to pump slurry containing over 15% solids into the system, while the inline grinder reduces particle size in the slurry stream and facilitates its pre-processing. At the same time, we upgraded few of the system fittings (check valves with limiting clearances) that further reduce the potential for clogging. All these have enabled us to start treating WAS (Waste Activated Sludge) for the first time - as shown in the video (click the image above to play video). Additionally, we have updated our start up procedure to improve the overall reactor temperature stability during runs.

New lobe pump, grinder and auger delivered ~ June, 2018

Our new pre-feed pump integrated with an auger feed and inline grinder have been delivered. This equipment will streamline the pre-processing required for treating sludge, enable us to test higher solids percent sludge and create opportunities to diversify our feedstock with food waste, biomass and industrial waste which will ultimately reduce and eliminate our reliance on co-fuels.

Our new pre-feed pump integrated with an auger feed and inline grinder have been delivered. This equipment will streamline the pre-processing required for treating sludge, enable us to test higher solids percent sludge and create opportunities to diversify our feedstock with food waste, biomass and industrial waste which will ultimately reduce and eliminate our reliance on co-fuels.

Work is proceeding to get the new equipment set up and commissioned early next month. We have been improving our software algorithm and interlocks, that significantly reduce our overhead, startup and shutdown time. We have also made the effort to replace the air positioner while the new one has been installed and calibrated promptly.Lastly, we decided to measure the sound level around the SCWO unit during operation. The main attribute for the noise is the air compressor measuring 83 dB at the container wall (OSHA's limit without requiring hearing protection is an average of 85 dB over an 8 our shift). With future sound proofing on the compressor and during the time the compressor was off, the loudest sound measurement outside of the container was 75 dB. The background measurement with the system off was 70 dB.

Improving oxygen consumption ~ May, 2018

This month we preformed system upgrades in order to facilitate the reliability testing process and improve the performance of the SCWO prototype. We added a liquid and gas separator to the sample port to make taking samples easier. We updated the furnace control logic to reduce the magnitude of temperature swings during steady state. We noticed a remarkable improvement in the amount of excess oxygen the system was using the for the reaction while still maintaining over 99.6% conversion. At the same time, we continued testing the efficiency of the SCWO process and spiked the biosolids feedstock with high levels of Urea and learned that it gets broken down to Ammonia.

Shelly Eisen Livneh joins the SCWO team ~ April, 2018

Shelly joined the team as the Product Marketing Manager to facilitate the project management and help commercializing the SCWO technology. During thismonth we hosted Sun Kim and Erin McCusker from the Bill & Melinda Gates Foundation, shared our progress and presented our testing and technology risk reduction plans for the next two years. We also discussed paths to technology commercialization.

Shelly joined the team as the Product Marketing Manager to facilitate the project management and help commercializing the SCWO technology. During thismonth we hosted Sun Kim and Erin McCusker from the Bill & Melinda Gates Foundation, shared our progress and presented our testing and technology risk reduction plans for the next two years. We also discussed paths to technology commercialization.

Began testing hazardous waste spiked feedstock ~ March, 2018

Polyfluorinated micro-pollutants are currently not being treated by traditional wastewater treatment plants and are persistent in the environment. We decided to rise to the challenge and spike the influent with PFOS and PFOA to test its conversion during the SCWO process. Analyses are pending.

System upgrades ~ February, 2018

Improved energy efficiency, depressurization capillaries and backpressure regulator for improved stability during operation. New CO, CO2, and O2 gas sensors were installed and integrated into the control system. We did not install SOx, NOx or NH3 sensors as grab sampling and analysis showed that the exhaust gas concentration of these gases was always below 3 ppm.

Exploring application in animal waste treatment and the effects of system capacity ~ January, 2018

Our team is using Aspen Plus to model and scale up the SCWO process for the treatment of animal waste (e.g., swine waste at confined feeding operations, or cafos) and has come up with capital and operating expenses estimates for systems of various sizes up to 30,000 people per day or farms with 10,000 hogs.

Image source: Wikimedia

Longer runs and more testing with pharmaceuticals spiked feedstock ~ November, 2017

November has been an eventful month for the SCWO team. We performed one of our longest runs during which the system was operational for 2 days straight. Additional insulation was added to the slurry lines in order to reduce heat losses. At the same time, we conducted more runs with sludge spiked with pharmaceuticals such as Ibuprofen, Acetaminophen and Triclosan and could not detect them in the effluent. This indicates that removal exceeded 99.99%.

November has been an eventful month for the SCWO team. We performed one of our longest runs during which the system was operational for 2 days straight. Additional insulation was added to the slurry lines in order to reduce heat losses. At the same time, we conducted more runs with sludge spiked with pharmaceuticals such as Ibuprofen, Acetaminophen and Triclosan and could not detect them in the effluent. This indicates that removal exceeded 99.99%.

Project review at the BMGF ~ October, 2017

Slurry Heat Exchanger Clog ~ September, 2017

In late August we experienced a clog in the slurry side of the slurry heat exchanger during steady state operation. Slurry ran through the outer annulus of this coil-in-coil heat exchanger. Attempts to clear the clog with acidic and caustic chemicals and flushing failed, and it was ultimately decommissioned and cut open. The clog appears to have been the result of small clearances in the outer annulus of the coil-in-coil design combined with the high viscosity of the feed stock.

In late August we experienced a clog in the slurry side of the slurry heat exchanger during steady state operation. Slurry ran through the outer annulus of this coil-in-coil heat exchanger. Attempts to clear the clog with acidic and caustic chemicals and flushing failed, and it was ultimately decommissioned and cut open. The clog appears to have been the result of small clearances in the outer annulus of the coil-in-coil design combined with the high viscosity of the feed stock.

New slurry pump on site ~ June, 2017

A new, custom dual piston slurry pump built by Terrasimco is being commissioned in the SCWO prototype after undergoing testing with solids slurries at high pressure at the manufacturer. The pump was designed to reliably pump high viscosity slurries at lower flow rates and with a larger maximum particle size than our previous slurry pump.

11 hour run with biosolids ~ May, 2017

On May 31, 2017, with the help of our two new operators, Luke Amrhein and Mahendra Joshi, we ran for 11 hours in steady state condition with a feedstock of 5% solids and 5% isopropyl alcohol (IPA)--the energy equivalent of 15% solids. Organic conversion was 99.9%, and the run rate represented the equivalent of 1,350 people/day.

Luke joined Duke in May from a local engineering lab, and Mahendra is a Duke MS student in Turbomachinery Aeromechanics working with us for the summer.

Energy recovery investigation ~ April, 2017

Over the past 10-12 months, the team has been evaluating the energy efficiency of the current prototype and investigating the energy efficiency and energy recovery potential for the next generation design. We've considered a range of energy recover technologies, system designs and scaling factors to maximize the energy balance of the second generation prototype. Preliminary designs are being modeled and refined with the help of a consultant, Dominion Engineering.

Image from: http://www.sciencedirect.com/science/article/pii/S1738573315001606

Sr. Process Engineer joins the team ~ February, 2017

Kobe Nagar joined the Duke SCWO team in February, 2017. He brings over 15 years of experience in the chemicals, power and defense industries. Kobe is taking the lead on energy recovery and the design of the next generation SCWO prototype.

Increasing our operational support ~ September, 2016

Walt Beckwith joined Duke in September, working part time and bringing a wealth of valuable hands-on experience with industrial equipment and processes. Walt contributes to the design, specification, commissioning, operation and maintenance of the SCWO prototype and its components.

Most successful solids run to date ~ June, 2016

On June 23 we ran the prototype for five hours in steady state on a feedstock slurry of 10% dog feces solids. This was both our longest run in steady state and the highest concentration of solids we've run. A co-fuel of 4% isopropyl alcohol was added to the feed slurry, but the solids quantity processed represented the waste of about 200 people. COD removal was very high, >99%. The system effluent was clear and free of odor. The ash particle size was small and settled out easily. The run was ended with a controlled shutdown when the feedstock was used up.

On June 23 we ran the prototype for five hours in steady state on a feedstock slurry of 10% dog feces solids. This was both our longest run in steady state and the highest concentration of solids we've run. A co-fuel of 4% isopropyl alcohol was added to the feed slurry, but the solids quantity processed represented the waste of about 200 people. COD removal was very high, >99%. The system effluent was clear and free of odor. The ash particle size was small and settled out easily. The run was ended with a controlled shutdown when the feedstock was used up.

Feedstock pre-processing results ~ May, 2016

In preparation for upcoming solids testing, preprocessing methods to reduce the particle size of our feedstock below 200 micron have been investigated to accommodate the specifications of the double-hose diaphragm slurry pump. Multiple feedstocks were considered: chicken and cow manure, dog feces and biosolids from a local wastewater treatment plant. The dog feces and biosolids could be processed using a combination of a shearing mixer and colloid mill. Up to 99% of the biosolids and 90% of the dog feces slurry particles were reduced to less than 200 µm. The viscosity of the biosolids slurry was significantly higher than that of the dog poop due, perhaps, to polymers added to the biosolids during dewatered.

Two new SCWO specialists join the team ~ February, 2016

Florencia Yedro started at Duke January 18. She joins us from the University of Valladolid, Spain where she completed her PhD in the High Pressure Processing Group.

Sherif Elsayed started at Duke on February 15. He joins us from the Karlsruhe Institute of Technology where he worked on his PhD in Supercritical Water Gasification.

Article Published in 'Journal of CO2 Utilization' ~ June, 2016

In an article titled “Separation of N2/CO2 Mixture Using A Continuous High-pressure Density-driven Separator”, Reza Espanani and colleagues from the Carbon Recycling Center at the University of Missouri demonstrate the possibility of capturing CO2 produced by supercritical water oxidation before it is released into the atmosphere.

Article Published in 'Chemosphere' ~ December, 2015

Andy Miller et al. article titled “Supercritical Oxidation of a Model Fecal Sludge Without the Use of a Co-fuel” describes the bench scale SCWO reactor used at the University of Missouri to inform the design of the prototype built at Duke. The effects of temperature, pressure, feed concentration and excess oxygen level on the conversion and heat transfer efficiency were evaluated using a factorial design.

UNC Water & Health Conference & Symposium on Supercritical Fluids ~ October, 2015

Primary Investigator (PI) Marc Deshusses presented the project at the University of North Carolina's annual Water & Health conference October 28, 2015 in a session on wastewater treatment. Click on the image to the right to view his presentation.

CO-PI, Dr. William Jacoby presented the project in a talk titled “Continuous Treatment of Fecal Sludge in a Technical-scale Supercritical Water Oxidation System” at the 11th International Symposium on Supercritical Fluids” held October 11th-14th, 2015 in Seoul, South Korea.

Completed Liquids Testing ~ October, 2015

Liquids experimentation was completed in October. Detailed analysis of the results followed in November. The team began investigating and designing a fecal sludge pre-processing system which provides particle size reduction to support successful slurry pumping and subsequent solids testing. We are also considering alternate feedstocks for testing since the biosolids we have been using contain additives that facilitate agglomeration.

Liquids Testing ~ July, 2015

Since May, we have been running the prototype on isopropyl alcohol at various feedstock  concentrations and flow rates to test the operating range of the system. We are analyzing COD (Chemical Oxygen Demand) removal and temperature profiles in the reactor and heat exchangers. We are also measuring O2, CO2 and CO in the vapor effluent to confirm that in steady state, the organic matter fed into the system is converted to CO2 and H2O. Running at supercritical conditions for over 130 hours has uncovered mechanical issues in the system which we’ve addressed along the way. We are currently testing lower feed concentrations at higher flow rates that reflect our original target operating specifications of ~1000kgwet/day flow rate with 10-20% solids.

concentrations and flow rates to test the operating range of the system. We are analyzing COD (Chemical Oxygen Demand) removal and temperature profiles in the reactor and heat exchangers. We are also measuring O2, CO2 and CO in the vapor effluent to confirm that in steady state, the organic matter fed into the system is converted to CO2 and H2O. Running at supercritical conditions for over 130 hours has uncovered mechanical issues in the system which we’ve addressed along the way. We are currently testing lower feed concentrations at higher flow rates that reflect our original target operating specifications of ~1000kgwet/day flow rate with 10-20% solids.

Oxidized Fecal Sludge ~ May, 2015

On May 8, we successfully oxidized fecal sludge in the SCWO prototype for the first time. The bottle on the left contains a sample of the feedstock fed to the reactor; the bottle on the right shows the reactor effluent. For this initial test, we prepared a slurry with 3% solids fecal sludge and isopropyl alcohol mixed in as a co-fuel. We ran the system while continuously pumping this slurry for 3.5 hours. The solids at the bottom of the effluent vial are comprised of harmless salts that precipitate at supercritical conditions. This successful run marked the departure of veteran project engineer Doug Hendry and the arrival of our new engineer, Kura Duba.

Convening at Duke ~ March, 2015

In March, Program Officers Carl Hensman and Sun Kim from the Gates Foundation spent the day at Duke getting an update on our progress. They were able to see the reactor in operation and tour the container after cool-down. Bill Jacoby, our co-PI from the University of Missouri was here for his first visit, along with his doctoral student, Andy Miller. Duke's Jay Golden presented the economic model he has been developing with support of his graduate students. Kura Simon Duba who recently earned his PhD in supercritical fluids from the University of Trento was also able to join us. Kura will be starting full time on the project in the end of April.

Oxidizing IPA ~ February, 2015

In January, we began introducing dilute isopropyl alcohol (IPA) to the system and reached supercritical temperature and pressure. We have been running the prototype once or twice a week, fine tuning operation and the start-up procedure. In February we achieved steady state operation with full conversion of 6-8% IPA. Data collected during operation with IPA is enabling us to characterize and optimize heat transfer throughout the system and prepare for upcoming treatment of fecal sludge.

In January, we began introducing dilute isopropyl alcohol (IPA) to the system and reached supercritical temperature and pressure. We have been running the prototype once or twice a week, fine tuning operation and the start-up procedure. In February we achieved steady state operation with full conversion of 6-8% IPA. Data collected during operation with IPA is enabling us to characterize and optimize heat transfer throughout the system and prepare for upcoming treatment of fecal sludge.

PLC and leak testing ~ December, 2014

In December, leak testing was successfully performed starting with low pressure air and working up to air and water at high pressure (3700 psi). The control system is operating reliably to date with ~75% of all control loops tested. Refinements in the system’s start-up procedure and equipment modifications have been made based on experience gained over numerous runs and varying conditions.

Piping complete ~ November, 2014

In November, the final connections were made to what is now a closed system. Leak testing and control system testing began. Insulation was partially installed to ensure proper piping and thermocouple alignment. The insulation will be completed before testing at high temperatures begins.

Pressure Vessel Code Inspection ~ October, 2014

In October, the NC Department of Labor reinspected our air tank and pressure relief valve configuration and confirmed it qualified for pressure vessel code certification. See the 'Photos and Videos' tab for photos of the capilary tubing that was installed as well as the control system interface. Fault code programming and data logging were completed, making the control system ready for testing.

Heat exchangers installed ~ September, 2014

In September, the last major component of the system, the custom designed heat exchangers were installed in container. The heat exchangers use a coil in coil design. As the process effluent flows through the inner pipe, it heats the water and air flowing through the upper outer coil and the slurry flowing through the lower outer coil.

Operation of Feluwa slurry pump ~ August, 2014

The Feluwa high-pressure slurry pump was run at our designed operating pressure, another successful step in the control system programming well underway.

Furnace, compressor and water pump tested ~ July, 2014

With power to the container, the bake-out procedure was performed on the Mellen furnace, the compressor and water pump were tested, and the control system software was employed to run the equipment for the first time. The control system logic underwent a detailed review.

480v power turned on ~ June, 2014

In June, our container’s electrical system passed inspection, and we were able to power up the unit for the first time. In addition to the main disconnect on the outside of the container, two power panels, a control panel, overhead lights and power outlets had been installed inside the container. This opened the door for component level testing of equipment.

Furnace mounted ~ April, 2014

Large components including the furnace and the high-pressure water pump were being mounted in the container. Electrical work to bring 480v electricity from a neighboring university building into the container was well underway. Procurement continued and entered its final stage.

Toilet Fair in Delhi, India ~ March, 2014

Six members of the SCWO project from Duke and the University of Missouri attended the Toilet Fair in Delhi co-hosted by the Government of India’s Biotechnology Department and the Bill & Melinda Gates Foundation. The fair provided a unique opportunity to talk to practitioners in the field, other research teams and entrepreneurs.

Milton Roy water pump in house ~ December, 2013

By the end of 2013, the prototype’s high pressure separation and depressurization system was designed, and the Feluwa high pressure slurry pump was ordered. ChemCAD temperature modeling of the prototype design was achieved with the help of Battelle. At the same time, the lab-scale SCWO unit at the University of Missouri was successfully oxidizing simulant using air as an oxidant.

Technical design review with Battelle Corporation ~ October, 2013

Duke entered into an agreement with Battelle in August, 2013 to provide technical consulting on the design of the supercritical water oxidation prototype. In October, the Duke team met with experts from Battelle in Richmond, Kentucky and toured the BGCAPP SCWO plant under construction there.

Shipping container delivered ~ September, 2013

The 20’ x 8’ x 8’ shipping container painted in Duke-blue was positioned behind Hudson Hall at the Pratt School of Engineering on Duke’s main campus. Meanwhile, prototype design was entering its final stage, and the procurement of parts was ramping up. Key components such as the air compressor and furnace were ordered.

Jose Abelleira joins the team ~ April, 2013

In August, 2013, Jose Abelleira came to Duke as a postdoctoral associate from the University of Cadiz in Spain, bringing with him experience in the design, construction, modeling and operation of SCWO systems.

The project begins ~ April, 2013

Duke University in collaboration with the University of Missouri was awarded $1.18 million from the Bill & Melinda Gates Foundation to design, build and test a prototype fecal sludge treatment system based on supercritical water oxidation technology. Marc Deshusses, Doug Hendry and Kathy Jooss represented the project team at a Gates Foundation grantee convening in Barcelona, Spain.